In industrial machining and heavy equipment repair, thread cutting is a critical yet demanding task. Among the tools most often relied upon for this operation are pipe taps, which are essential for cutting or restoring internal threads in pipes and fittings. Such taps have to perform at high pressure, friction, and high temperatures, particularly when applied in hard AC, such as cast iron or stainless steel.

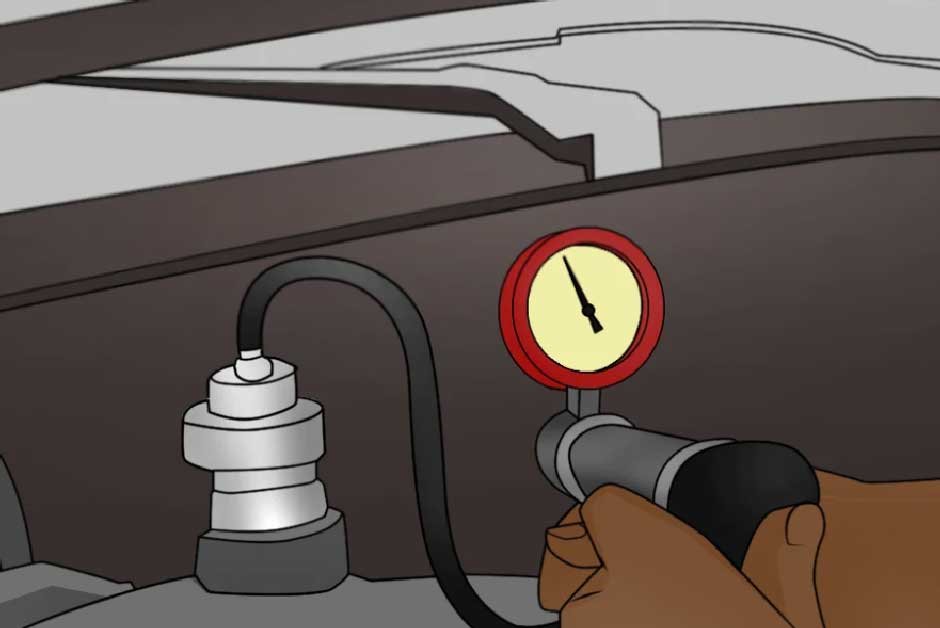

Coolant pressure is one of the key factors that determines the efficiency and lifespan of these tools. Appropriately used, the coolant can aid in increased ease of cutting. Also, it can phenomenally increase the lifespan of the tap.

Coolant pressure can help manufacturers increase their productivity, reduce tool wear and tear, and minimize downtime, which is a significant cost, as it deprives manufacturers of business opportunities.

How Coolant Pressure Affects Tap Performance

There are various essential functions of coolant in the tapping process. It is mainly used to dissipate the heat produced by the friction between the tool and the workpiece.

When a tap enters a hole and begins forming threads, the metal-to-metal contact, especially in deeper or blind holes, produces significant heat. Such heat, in the absence of adequate cooling, may lead to undesirably high rates of tool wear, material deformation, and even tap breakage.

Proper coolant pressure ensures that the liquid reaches the cutting edges of the tap and flushes out chips or debris, which can otherwise interfere with the cutting process and damage the threads.

Reduced Friction and Lower Torque Requirements

The reduction in the level of torque required when tapping is one of the measurable advantages of using high coolant pressure. Also, too much torque may cause a tap to break, particularly in harder materials or in deep holes.

Coolant relieves the tap of friction, which in turn enables it to cut more easily and without so much resistance. This not only shields the tool against strain but also minimizes the load on the tapping machine or manual tool.

Lower torque requirements mean the same tap can be used over a more extended period without compromising the quality of the threads or the safety of the operation.

In environments where pipe taps are used frequently for hydraulic port repair, equipment maintenance, and field service, reducing torque has a direct impact on both productivity and cost.

Taps that experience less friction and resistance have a slower wear rate, and technicians can perform more taps on them before they have to change taps.

Heat Management and Tool Longevity

One of the common enemies of a cutting tool is heat. Given uncontrolled conditions, it may make the cutting edges of a tap soften or become brittle, therefore splitting in advance.

The cooling feature released this tremendous pressure through the high-pressure coolant as a heat inhibitor that does not harm the tool.

This is critical, especially when using alloy steels, titanium, and other sensitive materials that are a common heavy equipment component.

Improved Thread Quality and Surface Finish

Coolant pressure also plays a role in improving the quality of the threads being cut. By removing chips from the cutting zone and keeping the tap lubricated, coolant helps produce cleaner, more accurate threads with a superior surface finish.

This is particularly important for pipe taps, where the taper must be precise to ensure a pressure-tight seal. Threads cut in dry or poorly lubricated conditions are more likely to exhibit tearing, galling, or uneven finishes, which can compromise the integrity of the seal and lead to rework or part rejection.

Cost Savings Through Extended Tool Life

From an operational perspective, prolonged tool life with optimum coolant pressure leads to the saving of vast amounts of money. Taps are very costly, particularly those that are industrial-grade. They might take up a considerable part of the maintenance budget and compromise the efficiency of shops when changed frequently.

The coolant systems under high pressure may involve an initial investment, but they save time and pay off quickly by increasing the number of cycles that a single tap can run through.

Conclusion

Coolant pressure is not merely a supporting factor of the tapping operation; it is a performance factor as well as a cost-saving device.

By managing heat, reducing torque, improving chip evacuation, and protecting cutting edges, coolant pressure plays a central role in extending the life of pipe taps.

For industries that depend on reliable threading in critical applications, understanding and applying the proper coolant strategy can lead to smoother operations, higher-quality threads, and fewer tool failures.

In the long run, investing in appropriate coolant delivery is not just good practice but essential for achieving the full potential of your tapping tools.