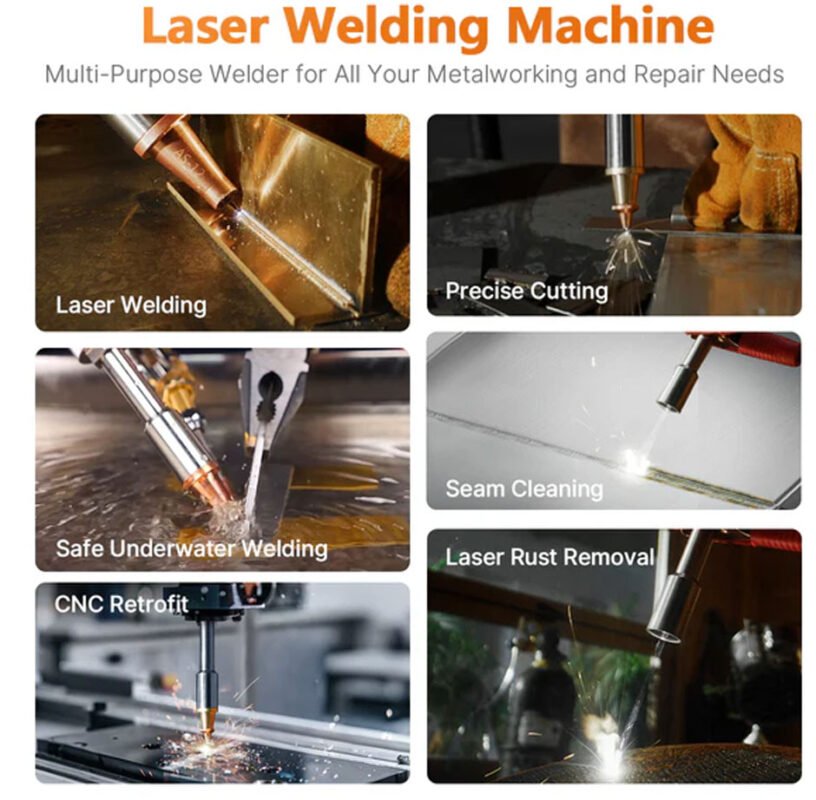

Xlaserlab has confirmed that they have launched the X1 pro, the universal fiber laser welder cutter, which incorporates welding, cutting, and cleaning surfaces into one set. The current trend of efficient, versatile, and mobile metal-processing solutions in various industries is expected to keep rising, and with the assistance of the system, the demand is set to be met. With the X1 Pro, the manufacturers, service providers, and repair teams of mobile phones will be able to perform the complex metal tasks more easily, reliably, and safely, with several functions to be performed on one platform.

This tendency towards the increase of the pool of multifunctional laser systems evidences the presence of an even more important tendency in the contemporary world of manufacturing to unify equipment and decrease downtimes. The welding, cutting, and cleaning are now provided with great precision at no cost to purchase an individual machine, which leads to increased efficiency of the working process and also saves money. It is also an internal fiber laser engraver, which is another enhancement of the device that allows marking parts and tracing them within the house or within the production/repair process. This integration of functions is leading to high usage rates in the automotive industry, the electronic industry, the aerospace and the industrial maintenance industry.

Little or big Characteristics and Professional Characteristics

The X1 Pro does have a fiber laser of 700 W and 1080 10 nm that enables it to be employed with stainless steel, carbon steel, aluminum, copper, brass, nickel alloys, and galvanized sheets. It also functions on the thickness between 0.5mm and 3mm of materials, providing it with appropriate performance in fine-artistry and heavy-duty operations. It is mobile with a weight of 21 kg and can be moved around, such that it can be utilized in a mobile form and at the same time can be able to perform at a professional level of industrial performance in the workshop or the production floor.

It also has an air-cooled system, which is stable when used under the condition of prolonged use, d touchscreen HMI, which can be designed to have a design that enables it to easily change modes and adjust parameters using various materials. Programmable settings make operators adjust welding, cutting, and cleaning within seconds and are simpler and faster to program, and provoke fewer errors. Safety features are also incorporated in the system, and these features include a key-lock system, interlock, emergency stop, and grounding point, making the system easy to use in any environment.

Its design is flexible enough that it allows one fiber laser cutter-welder to replace several machines that are single machines. This conserves equipment and energy and also minimizes the space it would have occupied, in addition to facilitating a business to respond faster to the requests for services. The X1 Pro will be very helpful to the mobile repair vendors as they will now be able to go directly to the job location to do some welding, cutting, and cleaning without necessarily carrying more than one machine.

Other qualities that would be desired in the X1 Pro are accuracy. It possesses a limited scope of affected heat processing, which reduces the distortion, and the cost of post-processing is minimal. The built-in fiber laser marking feature offers the high accuracy of marking of the serial numbers, marking of components, and quality control records that improve the traceability and minimize the probability of a mistake. The cleaning processes, such as rust cleaning and paint cleaning on the surface, enhance the efficiency of the materials utilized in the welding industry or finishing, which further adds another level of efficiency in the operation.

The X1 Pro would be the most appropriate solution to mobile repair and on-location services due to its multifunctionality and compactness. The businesses would now be able to weld, cut, and clean their customers without carrying different machines, a fiber laser welder cutter to save time, not only on the expenses that are incurred when a business is established. Its flexibility, which comes with a precision of professional standard, enables the technicians to work with any material and thickness that ranging extended to automotive panels to industrial parts.

According to an Xlaserlab spokesperson, X1 Pro has been a significant development as far as multifunctional lasers are concerned. The business has been enabled by us to integrate welding, cutting, and cleaning processes into a specific machine, a solution that is flexible, efficient as well and safe. It enables quality work in the workshop and the field environment, and changes the image in relation to the metal processing work.

X1 Pro is especially appropriate in areas where precision, repeatability, and speed are highly required. It applies to automotive repairs to do welding, cutting bodywork, and cleaning without making use of numerous machines. The electronics manufacturers are able to cut or weld small components with the least amount of heat deflection, though their versatility and reliability would be found during the aerospace and industrial maintenance processes.

About Xlaserlab

Xlaserlab is one of the pioneers of laser technology, which is determined to provide solutions of multi-functionality to the available manufacturing and repair industries. X1 Pro is one system that is made up of a fiber laser engraver and a fiber laser welder cutter, and it enables precision, portability, and efficiency in one system. Xlaserlab continues to advance equipment, which makes the working process better, the cost of the working process cheaper, and the result of the high outcome in the various industrial applications.

Media Contact:

Xlaserlab

Website: www.xlaserlab.com

Email: info@xlaserlab.com