Skip to the good bit

ToggleThe introduction of advanced polymers has transformed precision manufacturing processes, offering properties such as lightweight construction, chemical resistance, and high strength. Polymer applications extend far beyond lightweight components. High-performance polymers like PEEK, PPS, and reinforced composites now serve in heavier-duty applications such as actuators, gear systems, and thermal shielding. However, challenges like thermal deformation, chip evacuation, and dimensional variations present new demands for machining, strict temperature control and efficient chip evacuation are essential during processing to prevent severe machining issues.

Selecting Appropriate Drill And Thread

Successful polymer processing requires not only suitable machine tools and machining methods—such as predictive modeling, multi-axis control, and hybrid processes—but also careful attention to selecting appropriate drill types and thread forms. These factors directly impact the reliability of components (e.g., connectors, housings, fasteners) in automated applications.

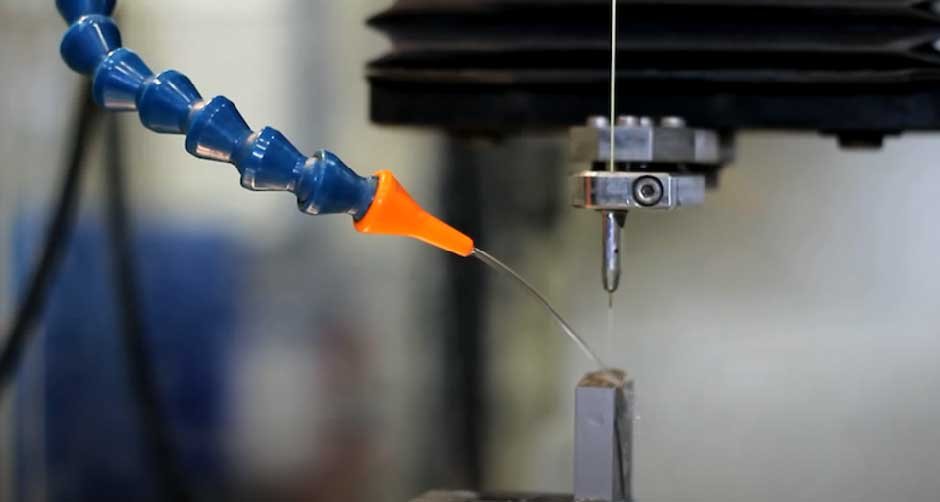

The type of the drill varies the heat of the cut, the straightness of the hole, and the smoothness of the surface. The correct drill bit types are very crucial in the beginning. Carbide drill bits and diamond-coated drill bits minimize heat generation during deep hole drilling and prevent chips from adhering or welding to the tool. Drills with large spiral flutes facilitate smooth chip evacuation, avoiding cracks in fiber-reinforced materials such as carbon fiber composites during machining. Engineers utilize these drills not only for rapid cutting but also to ensure consistent cutting depth and precise hole geometry.

Thread types also vary significantly, particularly when dealing with polymer parts, housings, or strong joints. Fine-pitch threads may experience “creep” (gradual deformation) under sustained torque, leading to stress concentration. Coarse threads, conversely, may strip (damage the thread) when torque direction changes. Therefore, engineering practice selects specialized thread forms with appropriate angles and circular profiles. This ensures load distribution across polymer fibers is more uniform, enhancing durability. Such thread design maintains joint stability under vibration, pressure fluctuations, and repeated heating/cooling cycles—critical for the reliability of automated systems.

Adaptive Process Control and Simulation

Prediction models on adaptive machining are highly dependent. Digital twins replicate the behavior of polymer such as its ability to stretch on the long run, its response to expansion due to heat, and irregular characteristics. The setting of feed speed, tool path, and depth of the cut in these simulations are such that we do not leave too much residual strain. They also forecast how drill bit types will interact with specific polymer grades, allowing selection of geometries that reduce chatter and prevent hole deformation. The models form a loop when we control them with sensors monitoring the process and make dimensions accurate in a few microns.

Digital analysis allows the selection of the thread types that fit into different builds in the fasteners. A load plot of threaded joints yields information about where the threads are to creep (stretch) or relax (loosen) when stressed. With the use of shapes of the threads so as to redistribute the load on the giant areas of polymer, engineers prevent the loosening of the fasteners at a young age. Combining simulated torque patterns with real time monitoring ensures that every joint remains stable even when employed under long load repetitions on robot automation.

Hybrid Workflow Strategies

Advanced polymers demand more than a single- method approach to machining. Hybrid workflows are a combination of more than one technique like mechanical, laser trimming, ultrasonic fanning and post-machining of the surface together into a single flow. Another typical example is the manufacture of robotic housings, starting with high-stability face milling to set up accurate datums, which is then followed by bore creation with optimized drill bit types. Chemical surface modification or plasma modification is then added to reduce friction or add bonding properties. Either step will add stability and any combination of these would help to avert thermal cracking, stress whitening or micro-level dimensional drifting failures.

The focus on joint integrity is particularly under consideration in this hybrid workflow. Torque-controlled tapping heads are often used by engineers to create thread types that are optimized to polymer to provide consistent engagement to avoid stress concentrations. Flank angle consistency, pitch accuracy, and thread depth are checked by optical metrology, because even small deviations diminish the load-carrying capacity. Such a sensitive combination of machining and inspection provides a closed loop structure that ensures assembly readiness at a point of manufacturing.

Hybrid workflow benefits also include the performance and reliability in the long run. Bores machined using newer drill bit types are selected because they exhibit better wear resistance and dimensional stability with repeated thermal cycles. Adaptive thread types used in assemblies ensure the preload stability under million cycles of operation. Combined, these findings indicate that structured hybrid approaches promote advanced polymers beyond supportive components to structural capability enablers in both aerospace and robotic automation.

Case Studies in Adaptive Polymer Machining

As case studies demonstrate, adaptive workflows transform policy onto polymer machining into an exact discipline. In one aerospace example, the actuator housings were made lightweight using drill bits restricting re-welding of chips. Specialized types of threads then served to hold bolt preload constant with vibration. Ultrasonic-aided finishing led to a 40% elongation of the service life and it brought about the dimensional stability.

In robotics, small on-board joint elements demanded internal profiles, which are constrained by conventional tooling. Engineers coupled laser-some drilling with precision tapping to land within tolerance windows of ±5 m. The adaptive thread types allowed progressive loosening to be avoided, whereas reinforced bores made using elevated precision drill bit types stood against the problem of thermal fatigue. These findings show that adaptive machining provides consistent performance in any industry.

Conclusion

Machining innovation for advanced polymers demands precision at every stage. Optimized drill bit types and adaptive thread types anchor this progress by ensuring structural fidelity under demanding loads. Together with digital modeling and hybrid workflows, these strategies enable polymers to fully realize their role in next-generation automation systems.