Metals play an integral part in modern society, used to create complex components in areas as diverse as construction and electronics, to mining, energy supply and transportation. They are chosen for their favourable properties – high tensile and compressive strength, electrical and thermal conductivity and the ability to be shaped and formed into the desired profiles and thicknesses. The materials are the mainstay of buildings and bridges, tools and household appliances, or cars, planes and trains.

However, well before becoming finished products, raw metal undergoes a series of fabrication processes to modify its shape, length, thickness and surface finish using a variety of metalworking machines. These apply pressure, heat or use tooling to process and transform raw metals into usable end products.

Common Metal Fabricating Techniques

The vast variety of metalworking machinery can be categorised by the metal fabrication process for which it is used. Raw metals are cut, formed, joined and cast. These basic processes either change the shape and size of the metal without removing material, join separate parts together to form a new component, remove excess and unwanted material or produce precision parts with complex geometries.

Basics of Metal Fabrication: Cutting

Cutting is defined as a subtractive process that removes excess material from the metal workpiece. It is a common fabrication method for transforming a metal sheet or a raw metal block into the desired shape, size, and finish. Cutting can be done using physical tools and applying pressure to the workpiece, using high heat, or high-pressure streams or electrical processes:

Mechanical Cutting Processes

These encompass turning, drilling, milling and sawing. Turning is a metal fabrication process that utilises a metal lathe to rotate a metal workpiece around a spindle, applying force via a cutting tool to machine the workpiece to the desired dimensions. This produces parts with round or cylindrical profiles and complex details such as internal and external threading, grooves and contoured shapes.

Common applications relying on lathes include the aerospace and automotive industries (transmission parts, suspension components, landing gear etc.), medical and healthcare sectors (surgical instruments, implants, laboratory equipment), power generation and utilities (turbines, shafts, pipes), general consumer items (furniture, tools, kitchenware) and more.

Drilling creates holes of varying thickness and varying depths, as well as enlarging existing homes (boring), creating conical holes for flush-fitting fasteners (countersinking), cutting internal threads (tapping) and machining smooth flat surfaces or spot facing. The process is integral to joining and part assembly using fasteners, manufacturing complex electronics, industrial machinery and automotive parts and more.

Common machines are pedestal drills, but different drilling processes can also be achieved with radial arm drills, mill drills and threading machines.

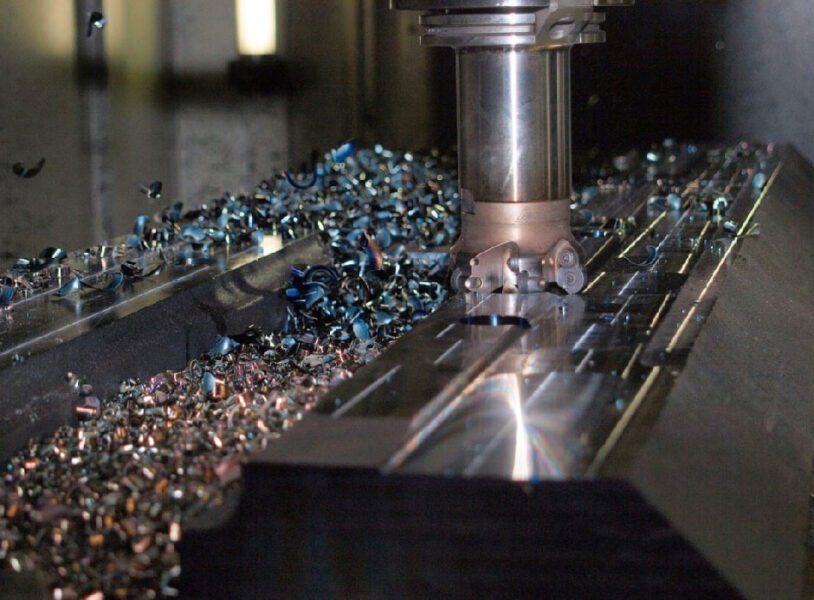

Milling involves removing excess material from a stationary workpiece using a rotary cutting tool. Compared to drilling, the process can produce more complex geometries with higher precision.

Parts made with mill drills and milling machines include brake and steering parts in cars, electronic enclosures and circuit boards, pumps, valves and gears in machinery, as well as prototypes and tooling used in casting and injection moulding, among other areas, often supplied by a gear manufacturing company.

Sawing is a fabrication process where metalworking machines such as cold saws, horizontal and vertical bandsaws and cutoff saws are used for making a variety of straight and angled cuts in metals ranging from steel and aluminium to copper and lead.

Thermal, Laser and Water-jet Cutting

Plasma and laser cutters use high temperatures to cut through metals of varying sizes and thickness. Laser cutters deploy a focused beam to melt, burn and vaporise materials and produce intricate designs and shapes in specialised fields and industries.

Plasma cutters use high-temperature plasma to cut through thick pieces of conductive metals such as copper, steel and aluminium, while water-jet cutters use high-pressure water jets to cut precise sections, especially in heat-sensitive and metals with lower melting points such as lead and aluminium.

Metal Forming

Forming is another key metal fabrication process that involves shaping metals using tension. The process is neither additive nor subtractive, meaning excess material is not removed or added to the workpiece. Common forming processes include bending – where machines like plate, angle, section and tube benders form metal sheet or billet into products such as cylinders, angled beams, and tubes.

Another forming process, extrusion, involves putting metal sheet and bar through dies and creating long, consistent profiles under extreme pressure. Similarly, (hot and cold) rolling reduces the thickness of raw metal into frames, automotive parts, appliances and metal sheeting for construction purposes.

Casting and forging are other metal forming processes that use pre-formed moulds to shape molten metal (casting) or very high pressure (forging). Common machines seen here are hydraulic and CNC press brakes; cluster, tandem and reversible rolling mills and single and double-screw extruders.

Joining

When joining similar or dissimilar metals, consider welding, brazing and soldering. All rely on the heat of ignited gases or electrical current to melt and fuse metals. Different welding techniques (MIG, TIG and stick) use filler materials (electrodes) of the same material as the workpiece to fuse ferrous or non-ferrous metals in the aerospace, automotive and construction industries.

Similar processes are soldering, which uses heat under the materials’ melting point to fuse workpieces (in electronics and jewellery making), and brazing (seen in pipe fittings, cooling systems, and metals of uneven thickness), which melts only the filler material.

Choosing the Right Machine for the Job

For high precision, increased productivity, ease of use and consistent and repeatable results, choose machines that are versatile and meet your metal fabricating needs. Determine where and how the machinery will be used, which metals you usually work with, and the level of precision and feature set you can’t do without.

Define which tasks and fabrication processes the machines will perform. More versatile and therefore more frequent choices seen in both smaller fabrication shops and larger mass-production facilities are lathes, milling machines, drill presses and press brakes. This covers the majority of general fabrication.

More specialised and undeniably more expensive pieces, such as laser cutters and waterjet systems required for high turnarounds and intricate details, may be an addition to a growing business or requirement in niche fabrication sectors.

On that note, also consider floorspace, required power supply, the ability to fabricate metals into different shapes and thicknesses, and accessories (such as tooling) and features that raise workplace safety, ensure fast turnarounds and lead to minimal maintenance.

The last question is whether to buy new or used. This is tied with budgets. Many new operations start with used, but well-maintained machines that are readily available, have a steady supply of tooling, accessories and parts and are already familiar to operators with simplified controls. Going new, on the other hand, ensures peace of mind with warranties, machines that are guaranteed to deliver results and pieces that can establish your business and help you grow.